Descripción

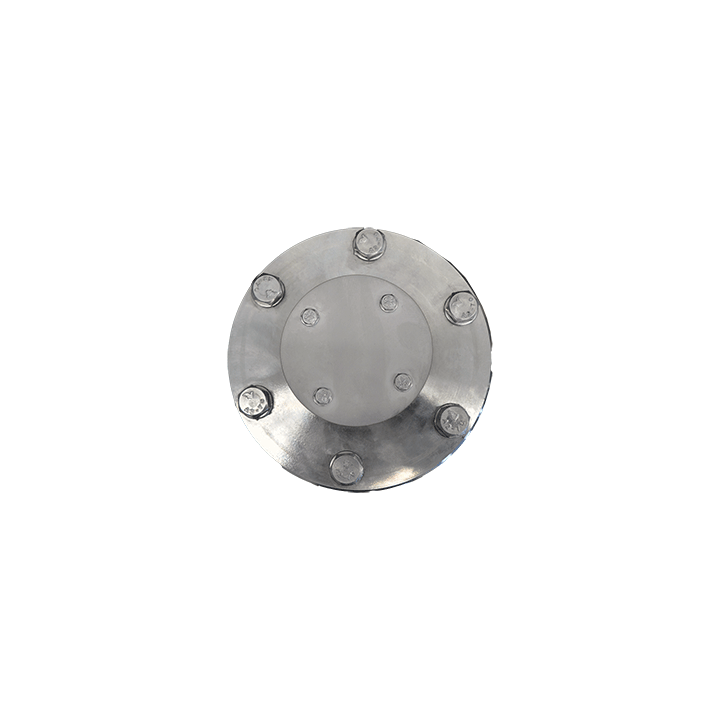

HR air valves are used to prevent explosion in the pipeline, as a result of air charge/discharge failure at system startup and shutdown; and during the operation. These valves consist of a body that contains two floats in different chambers that are placed at a predetermined height.

The main float is guided by a grooved box and moves when there is a change in water elevation. As a result of the valve’s streamlined design, the float remains completely stable under air intake/discharge, preventing premature closure.

Only when there is an increase in the water level, the float rises and closes the valve; and when the water level drops, the float lowers, allowing large volumes of air to enter the system. The second float is attached via a pin for quick reaction. So you can let the air out while the system is running.

STANDARD

- Design according to EN 1074/4 AND AWWA C512

- Pressure test according to EN12266

- Flanges according to EN1092-2

- Ductile iron according to EN1563

MAIN APPLICATIONS

- Distribution networks.

- Irrigation systems.

- Feed pipes.

- Changes in slope on ascending sections and high points of pipes.

FUNCTIONING:

Output of large airflows

During the filling of the main pipe it is necessary to release an air flow equivalent to the inlet water flow. Thanks to its aerodynamic shape of the body and the deflector, it avoids its early closure during this process, thus helping a total discharge of the pipe.

Controlled air outlet

During the filling of the pipe with water, a water hammer may occur, which causes an increase in air pressure inside the suction cup. If this happens, the upper disk rises and reduces the discharge of air, and consequently the speed of the approaching water column.

air purge

During the work of driving, small volumes of air accumulate in the upper part. Little by little the air is compressed, reaching the same pressure as the water inside. This pushes the water and float down, allowing air to escape.

Admission of large air flows

During the emptying of the pipe, either by necessity or due to breakage, it is necessary to introduce an air flow to the pipe, similar to that of the water that is being emptied. In this way depression conditions and damage to the network are avoided.